Understanding High-Pressure Die Casting: A Game Changer for EV Charger Shells

In the fast-evolving world of electric vehicles (EVs), innovation is crucial to staying ahead. One such innovation making waves in the manufacturing of EV charger shells is High-Pressure Die Casting (HPDC). This state-of-the-art technique not only streamlines production but also enhances product quality and performance.

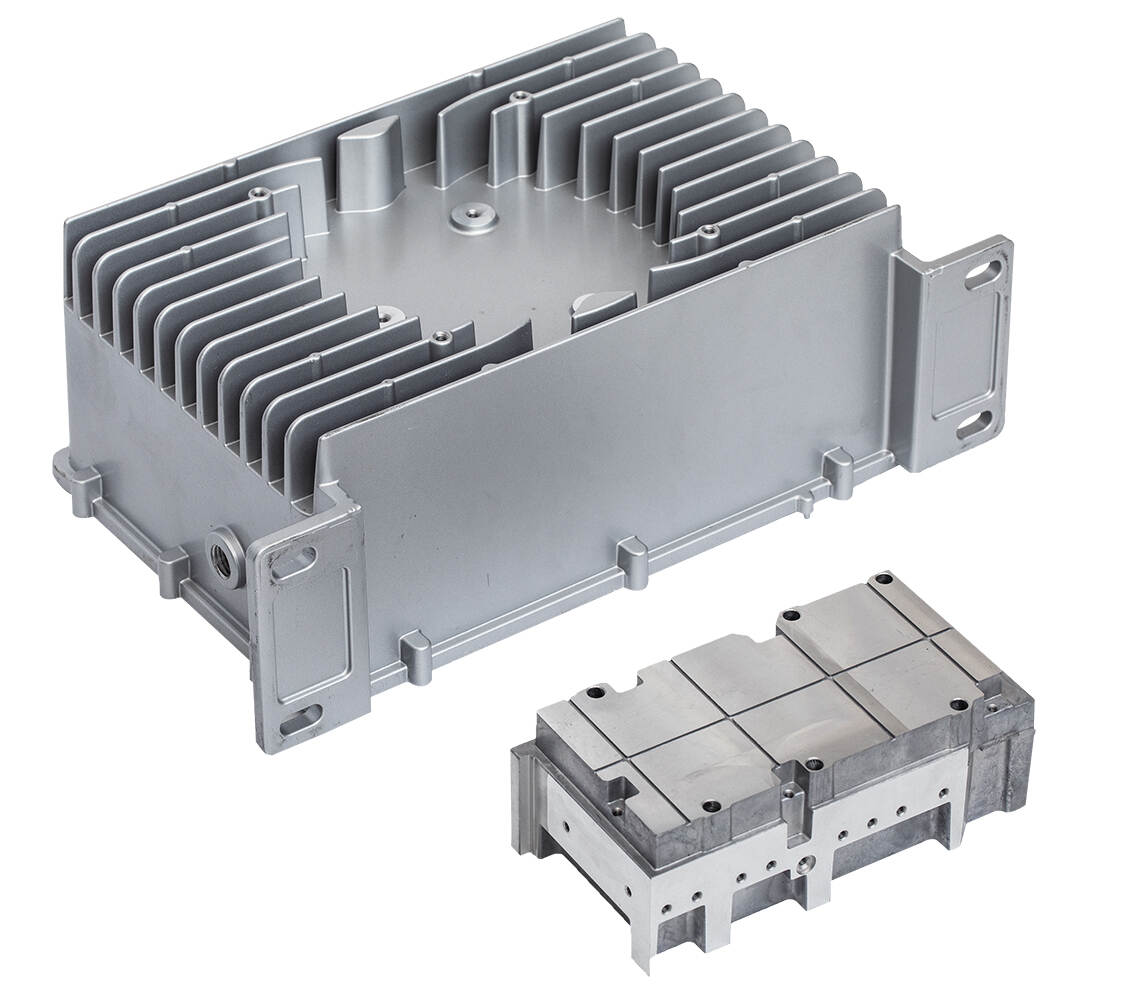

High-Pressure Die Casting is revolutionizing the manufacturing landscape by offering unmatched precision and durability, which are critical for components like EV charger shells. With an ability to form complex cavity shapes and thin-wall structures, HPDC is the go-to solution for realizing robust and lightweight designs.

The Tech Behind the Transformation

HPDC involves injecting molten metal into a steel mold under high pressure. This process ensures superior dimensional accuracy and a fine surface finish, reducing the need for additional machining. At Ningbo Seipo Machinery Co., Ltd., our expertise in HPDC allows us to produce EV charger shells with precision tolerances of ±0.05mm and a surface roughness of Ra ≤ 1.6μm, significantly cutting down on post-production costs.

The materials selected for this process, such as premium ADC12 and A380 aluminum alloys, are carefully chosen to balance strength and weight, providing a perfect fit for automotive applications. Our advanced HPDC technology supports intricate designs with a minimum wall thickness of 0.8mm, making it ideal for the lightweight requirements of modern electric vehicles.

Product Advantages and Solutions

Our OEM New Energy Car Charger Aluminum Alloy Die Casting for Shell, produced in China and available at competitive pricing (USD 15-20 per unit for orders over 50 units), exemplifies the capabilities of HPDC. With a monthly supply capacity of 100,000 units, we ensure that high demand can be met without compromising quality.

Beyond just manufacturing, Ningbo Seipo offers a comprehensive range of solutions that include CNC precision machining and diversified surface treatments such as anodizing and electrophoretic coating. This ensures that every EV charger shell not only meets but exceeds industrial standards for durability and aesthetic appeal.

Why Choose Our Services?

Operating from the heart of China’s mold industry in Ningbo, Ningbo Seipo Machinery Co., Ltd. has been at the forefront of die casting innovation since 2010. Our commitment to quality is backed by certifications like ISO 9001 and IATF 16949, and our services are trusted by global technology leaders like Huawei and DJI.

Our ability to fast-track production, coupled with extensive export experiences to markets in the US, EU, Japan, and Korea, positions us as a reliable partner in the automotive parts industry. For urgent requirements, our dual production bases in the Yangtze River Delta and Pearl River Delta can deliver within 7-10 days.

In conclusion, High-Pressure Die Casting stands as a transformative force in the manufacturing of EV charger shells, providing unmatched precision, efficiency, and reliability. By choosing Ningbo Seipo, you are not just opting for a product but a promise of excellence and innovation in the realm of automotive components.

For more information or to discuss your specific needs, contact us at harry@seipo.cn or visit our website.