Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How Seipo Became a Leader in Precision Die Casting for EV Chargers

How Seipo Became a Leader in Precision Die Casting for EV Chargers

Ningbo Seipo Machinery Co., Ltd. has firmly established itself as a leader in the precision die casting industry for electric vehicle (EV) chargers. Since its founding in 2010, Seipo has consistently delivered high-quality aluminum die casting solutions, meeting and often exceeding the stringent demands of automotive manufacturers around the globe.

At the heart of Seipo's success is our commitment to precision, innovation, and exceptional service. Our state-of-the-art facility in Ningbo, China, allows us to produce up to 100,000 EV car rechager cases each month. This robust production capability underscores our dedication to supporting the rapidly growing EV market.

Precision and Innovation in Every Product

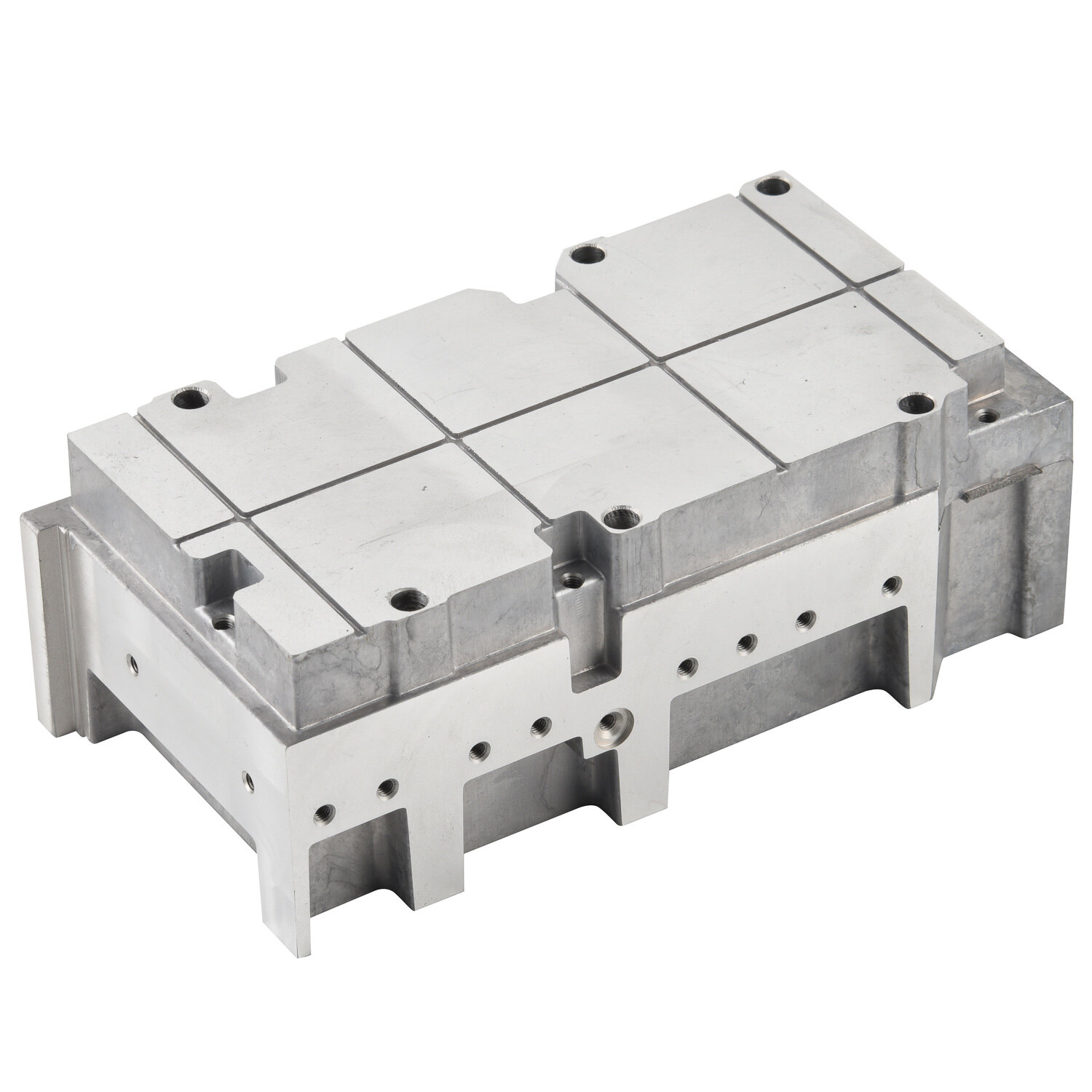

Our flagship product, the OEM New Energy Car Charger Aluminum Alloy Die Casting for Shell, exemplifies our dedication to quality and innovation. Crafted from premium aluminum alloys like ADC12 and A380, our die casting solutions provide the perfect balance of strength and lightness, essential for EV applications.

Seipo's advanced high-pressure die casting (HPDC) technology supports thin-walled structures with a minimum wall thickness of 0.8mm and complex cavity formations. Our products boast a dimensional accuracy of ±0.05mm and a surface roughness of Ra≤1.6μm, significantly reducing post-processing costs and ensuring a flawless finish.

Comprehensive Manufacturing Solutions

Beyond die casting, Seipo offers complete manufacturing solutions, including CNC precision machining and advanced surface treatments. Our five-axis CNC machines achieve ultra-high precision of ±0.02mm, facilitating intricate designs such as integrated antenna slots and heat dissipation structures. We enhance product functionality with diverse surface treatments, including anodizing, micro-arc oxidation, and conductive anodizing for EMI shielding.

Why Choose Seipo?

Seipo's commitment to quality is reflected in our comprehensive quality assurance system, which includes ISO 9001 and IATF 16949 certifications. Our rigorous testing protocols ensure each product meets the highest standards of reliability and performance.

Our strategic location near the Beilun Port in Ningbo enhances our logistical capabilities, ensuring timely delivery across major markets, including the USA, EU, Japan, and South Korea. With a flexible production model, we accommodate orders from small batch trials to large-scale production runs of up to 5 million units annually.

Seipo's dedication to innovation and excellence has attracted partnerships with global industry leaders, including Huawei and DJI, further cementing our reputation as a trusted supplier in the electronic casing industry.

For bespoke electronic casing solutions that deliver precision, reliability, and innovation, choose Seipo. Contact us at +86 13003774020 or email us at harry@seipo.cn to learn more about how we can cater to your specific needs.