Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Several points that must be noted for die cast use

Several points that must be noted for die cast use

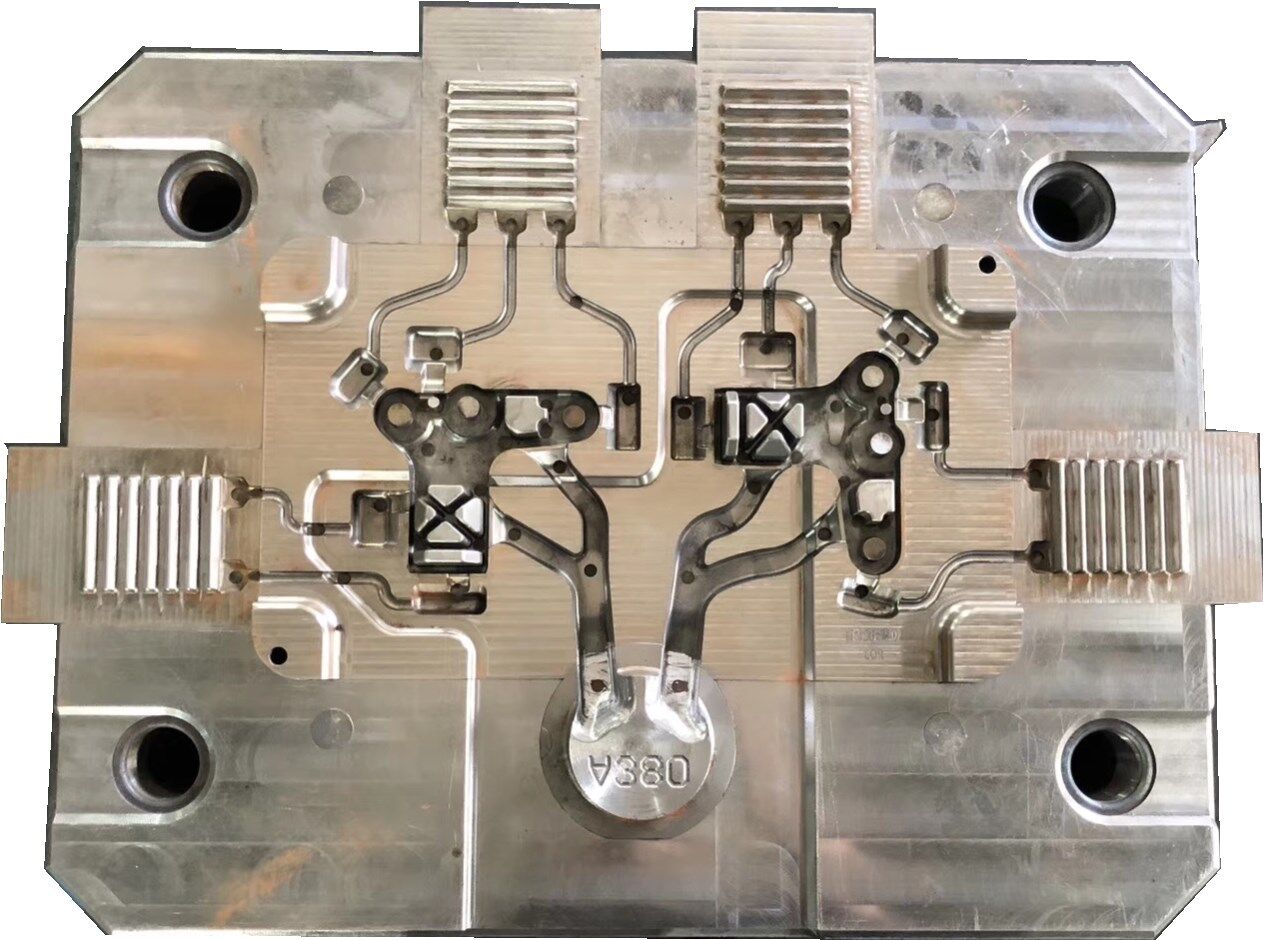

1, the use characteristics of the die-casting mold

The die casting process is terrible, they undergo mechanical abrasion, chemical erosion, and thermal fatigue.

1) The metal liquid enters the mold cavity at high pressure and high speed, causing fierce friction and impact on the surface of the mold cavity, and causing erosion and wear on the surface of the mold cavity.

2) In the pouring process of metal liquid, it is inevitable that slag into, slag has a complex chemical effect on the surface of the forming parts, aluminum and iron compounds like sharp split, accelerate the formation and development of die casting mold crack.

3) Thermal stress is the main reason for cracks on the surface of mold-forming parts. In the production process of each die casting part, the surface of the forming parts is washed by high speed and high pressure of metal liquid but also absorbs the heat released by the metal in the solidification process, resulting in heat exchange. In addition, due to the heat conduction of the mold material, the surface layer temperature of the forming part rises sharply, which produces a large temperature difference with the interior, resulting in internal stress. When the metal liquid fills the cavity, the surface layer of the cavity first reaches a high temperature and expands, while the inner layer mold temperature is low, and the relative expansion amount is small so that the surface layer produces compressive stress. After opening the mold, the surface of the cavity contacts with the air is cooled by compressed air and paint and produces tensile stress. This alternating stress increases with the continuation of production, and when exceeding the fatigue limit of the die material, the die surface layer produces plastic deformation and produces cracks.

In order to maintain the durability of the surface, the surface is required to have heat fatigue resistance, wear resistance, non-stick mold, easy to strip. Therefore, the current well-applied 4Cr5MoSiV1 (H13) material is used for the forming parts.

2. The temperature of the alloy melt

In order to better fill all the holes and depths of the metal flow, the metal casting temperature of the metal is as follows:

Material name Die-cast liquid temperature / ℃

Zinc alloys 420-500

Aluminum alloy, 620-690

Magnesium alloys 700-740

Copper-zinc alloy 850-960

Temperature selection principle of die-casting alloy:

1) The lower the temperature of the poured metal, the longer the life of the die;

2) Only with low temperature die casting is it possible to reduce the depth of the exhaust tank and reduce the danger of metal liquid splashing;

3) Low-temperature die-casting can reduce the tightening opportunity of the pressing chamber and the top rod;

4) Low-temperature die-casting can reduce the production of shrinkage holes and cracks in the casting.

In short, when the process conditions allow, the temperature of die casting alloy or choose the low temperature to die casting.

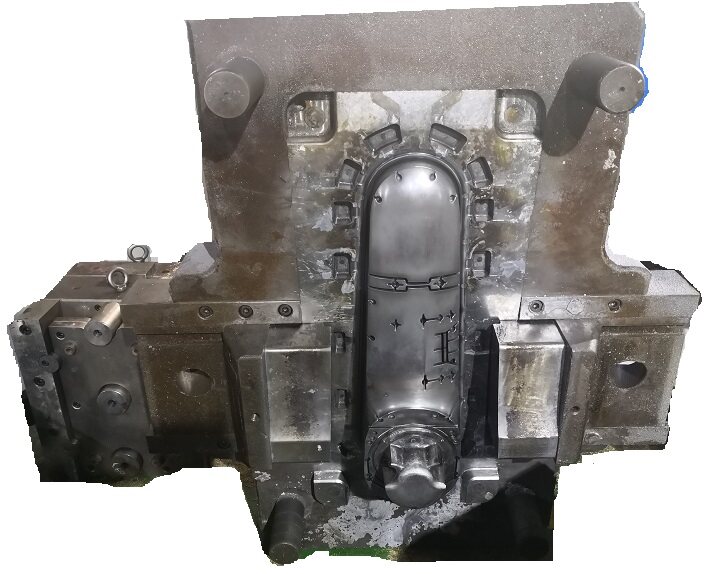

3, the working temperature of the mold work

The working temperature of die casting mold varies according to its die casting alloy. The following are the recommended values of several alloy molds for selection:

Mold name working temperature / ℃

Zinc alloy mold 150-180

Aluminum alloy mold 180-225

Magnesium alloy mold 200-250

Copper zinc alloy mold 300

Principle of working temperature of die casting:

1) The mold temperature is too low, the internal structure of the casting is loose, the air discharge is difficult, difficult to form;

2) The mold temperature is too high, the internal structure of the casting is dense, but the casting is easy to "weld" attached to the mold cavity, sticky mold

It is not easy to discharge the casting, and the high temperature will expand the mold itself, and affect the size accuracy of the casting.

3) The mold temperature should be selected within the appropriate range, generally, after the appropriate test, the constant temperature control is reasonable.

4, the lubrication of the die-casting mold

1). The purpose of lubrication

Lubrication acts as the separation agent for die-casting and die-casting; as the active part of the die-casting and press, reduces friction, improves the service life of die-casting, and reduces the die life due to thermal fatigue for long operation.

2). Lubricant requirements

The selection of lubricants shall meet the following requirements:

A. The die casting cannot adhere in the type cavity;

b.The steel material that can not corrode the mold type surface;

c.Unable to produce toxic gases;

d.Do not produce ash when heating;

e.After lubrication shall be evenly attached to the type cavity and working surface without being washed away by high-pressure metal.

3). Preparation of lubricant

a.Full loss system oil 85% -90% + graphite 10% -15%;

b.Heavy oil: 100%;

c.Paraffin 30% + yellow waxin 30% + Vaseline oil 14% + graphite 26%;

d.Graphite 25% + glycerin 20% + water glass 5% + water 50%;

4). Matters that should be noted when using lubricant

a.Lubricant can be used on the type cavity and movable part surface;

b.Lubricant spray amount should be less each time, and to be uniform, it is best to form a film on the type surface after spraying.

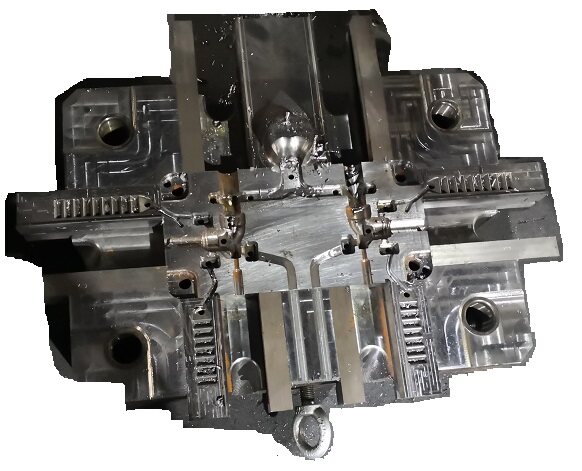

V. Adjustment content of the die-casting mold

After completing the die casting mold, it is necessary to adjust the correct die casting conditions and process parameters to achieve stable die casting and produce qualified castings.

Before the dying test, die test personnel shall check the alloy raw materials for die casting to understand the characteristics of the die structure, performance, conditions, process, and operation methods.

The correct selection of die-casting forming conditions is the key to die trial adjustment. Often encounter such problems, even if the design and manufacture of the mold are very correct, but due to the improper selection of die-casting and forming conditions, the same can not press the qualified casting. On the contrary, in some cases, the conditions of die casting can be adjusted to overcome the shortcomings of the mold, and press out the qualified cast. Therefore, the die test personnel must be familiar with the role and mutual relationship of the die casting conditions, the active principle of the mold, so as to correctly choose and reasonably adjust the die casting conditions.

The contents of die-casting forming conditions include: material melting temperature, die temperature and melt temperature, injection pressure, die locking force, die opening force, compression shot ratio, and burst speed required according to the condition of manufacturing parts. Finally, the die casting products should be repaired before obtaining the perfect die casting parts.