Aluminum die casting molds, known as HPDC (High Pressure Die Casting) molds, are essential in producing high-quality aluminum alloy parts with precision and excellent surface quality. These molds are widely used in various industries, including automotive, electronics, communication equipment, and aerospace. In this article, we will delve into the manufacturing process of HPDC molds, highlighting their features, advantages, and applications.

The Manufacturing Process Unveiled

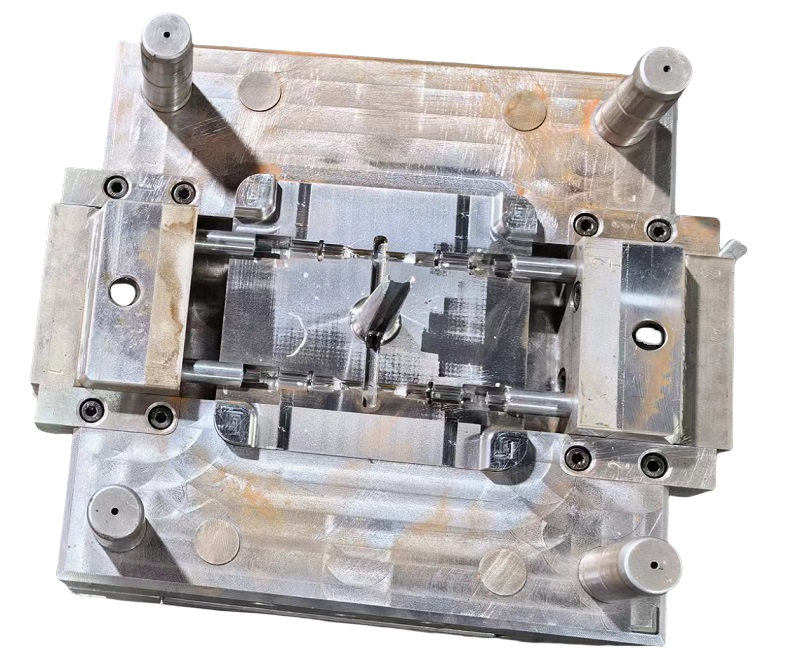

The creation of an HPDC mold involves several meticulously controlled steps to ensure high precision and durability. The process begins with the design phase, where computer-aided design (CAD) software is used to draft the mold's geometry. Once the design is perfected, it moves to the machining phase, where high-precision CNC machines shape the mold from robust materials such as steel. The machined mold is then polished and inspected for any imperfections before it is finally tested under high-pressure conditions with molten aluminum.

Key Features of HPDC Molds

HPDC molds are renowned for their ability to produce parts with high precision and excellent surface quality. Here are some standout features:

- High Precision: These molds can produce aluminum alloy parts with stable dimensions and high accuracy, catering to various industrial requirements.

- Excellent Surface Quality: The parts produced have smooth surfaces without porosity, significantly reducing the need for additional surface treatments and lowering production costs.

- High Strength: Aluminum alloy parts created using HPDC molds exhibit superior strength and hardness, making them suitable for high-load and high-pressure applications.

- Energy Efficient and Environmentally Friendly: The manufacturing process is straightforward, using recyclable aluminum alloy materials, aligning with modern energy-saving and environmental protection standards.

- Long Service Life: Made from high-quality materials and precision-machined, these molds boast a long lifespan.

Applications of HPDC Molds

HPDC molds are versatile and find applications across various sectors. They are extensively used to manufacture automotive engine parts, electronic housings, communication equipment components, and more. As industries continue to evolve and technology advances, the demand for HPDC mold products will only increase, driven by their unparalleled precision, strength, and efficiency.

Product and Service Overview

If you're looking for high-quality HPDC molds, Ningbo Seipo Machinery Co., Ltd. offers a reliable solution. Established in 2010, the company specializes in providing aluminum die casting production and machining services. With a monthly supply capacity of 15 sets and a range of supported payment methods like PayPal, VISA, MasterCard, and more, Seipo Machinery ensures a seamless purchasing experience.

The HPDC molds from Seipo Machinery are priced between USD 1,000 and USD 100,000, depending on the specifications and quantity. The products are shipped from Ningbo port and typically have a lead time of 45 days. You can view detailed product information and images on their product page.

Notably, Seipo Machinery's HPDC molds support various industries, including automotive, electronics, and aerospace, offering high precision and durability. To learn more about their offerings and services, visit their official website or contact them via phone at 0086 13003774020 or email at harry@seipo.cn.