Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How to Use and Maintain Your HPDC Mold

How to Use and Maintain Your HPDC Mold

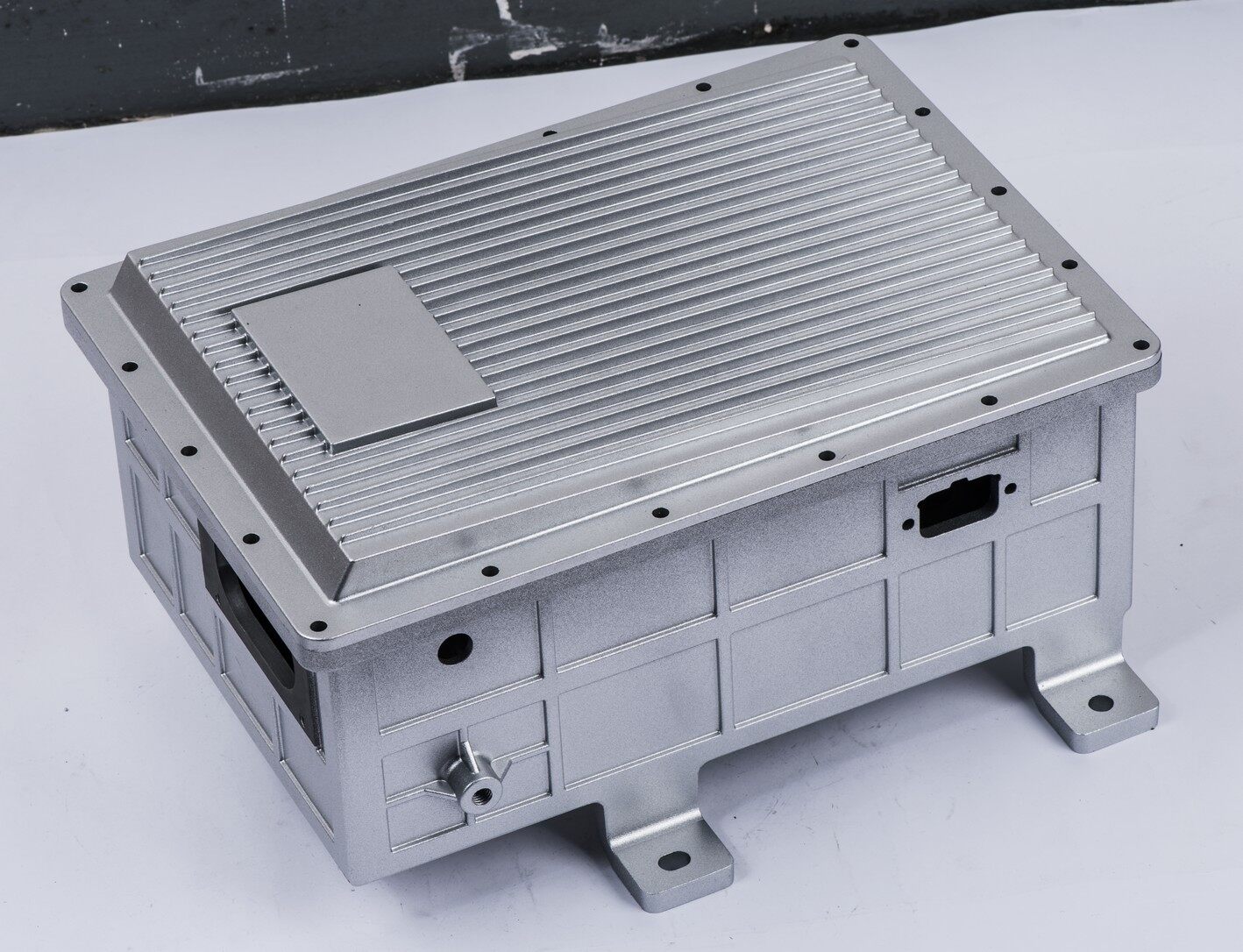

High Pressure Die Casting (HPDC) molds are essential tools in the manufacturing of high-quality aluminum alloy parts. These molds allow for the production of precision-engineered components that boast excellent surface quality and high strength. To ensure that your HPDC mold remains in optimal condition and delivers consistent performance, it is crucial to follow proper usage and maintenance guidelines. In this post, we will discuss some valuable tips on how to use and maintain your HPDC mold effectively.

Proper Usage of HPDC Mold

The use of HPDC molds requires a meticulous approach to ensure that the aluminum alloy parts produced meet the highest standards. Here are some key points to consider:

- Pre-heat the Mold: Before beginning the casting process, it is essential to pre-heat the mold to the appropriate temperature. This helps in reducing the thermal shock and prevents any potential damage to the mold.

- Use High-Quality Materials: Ensure that the aluminum alloy used is of high quality and free from impurities. High-quality materials contribute to the production of parts with superior strength and surface finish.

- Monitor Injection Parameters: Carefully monitor the injection pressure, temperature, and speed to ensure they are within the recommended range. Proper control of these parameters is critical for achieving precise and defect-free parts.

Maintenance Tips for HPDC Mold

Regular maintenance of your HPDC mold is essential to prolong its service life and maintain its performance. Here are some important maintenance practices:

- Regular Cleaning: After each production cycle, clean the mold thoroughly to remove any residual aluminum alloy and debris. This prevents build-up and potential damage to the mold surface.

- Inspection for Wear and Tear: Regularly inspect the mold for signs of wear and tear, such as cracks or deformation. Addressing these issues promptly can prevent further damage and costly repairs.

- Lubrication: Apply appropriate lubricants to the mold components to reduce friction and wear during the casting process. Proper lubrication also helps in achieving smooth and consistent operations.

- Storage: When not in use, store the mold in a dry and clean environment to prevent corrosion and damage from environmental factors.

Why Choose Our HPDC Mold?

At Ningbo Seipo Machinery Co., Ltd., we specialize in providing top-quality HPDC molds that cater to a wide range of industrial applications. Here’s why our HPDC molds stand out:

- High Precision: Our molds are engineered to produce high-precision aluminum alloy parts that meet stringent industrial standards.

- Excellent Surface Quality: Parts produced with our molds boast a smooth surface finish and are free from porosity, eliminating the need for additional surface treatments.

- High Strength: The aluminum alloy parts produced by our molds exhibit exceptional strength and hardness, making them suitable for demanding applications.

- Eco-Friendly: Our production process is designed to be energy-efficient and environmentally friendly, utilizing recyclable aluminum alloy materials.

- Long Service Life: Made from high-quality materials and precision-engineered, our molds have a prolonged service life, ensuring reliable performance over extended periods.

Our HPDC molds are available for delivery from Ningbo port, with a monthly supply capacity of up to 15 sets. We offer flexible payment options, including PayPal, VISA, MasterCard, Western Union, L/C, T/T, D/P, and D/A. For more information about our HPDC molds, please visit our product page at HPDC Mold.

Contact Us

If you have any questions or need further assistance, feel free to contact us at:

- Phone: 0086 13003774020

- Email: harry@seipo.cn

- Address: No.68, Dagang 2 Road, Beilun, Ningbo, China 315800

Visit our website for more information about our products and services: Ningbo Seipo Machinery Co., Ltd.