Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How many cavities should I build into my die cast mold?

How many cavities should I build into my die-cast mold?

One of the most critical decisions you will make when launching a new project is choosing the cavitation of your die cast tooling. The number of cavities in the die will affect the cost of your die, the casting price, and the life of your tooling. It is important to make an informed decision when investing in die-cast mold.

The top 3 factors to determine your cavitation are as follows:

- Size of the casting

- The complexity of the part

- Expected annual usage and life of the program

Continue reading for an in-depth review of the factors that impact your decision.

Size of the casting

It’s not the weight of the casting that is important, it’s the surface area. The casting machine size required to produce a part is determined by the surface area of the part, runner, and venting. The pressure applied to this surface is the force the casting machine must overcome when injecting the metal.

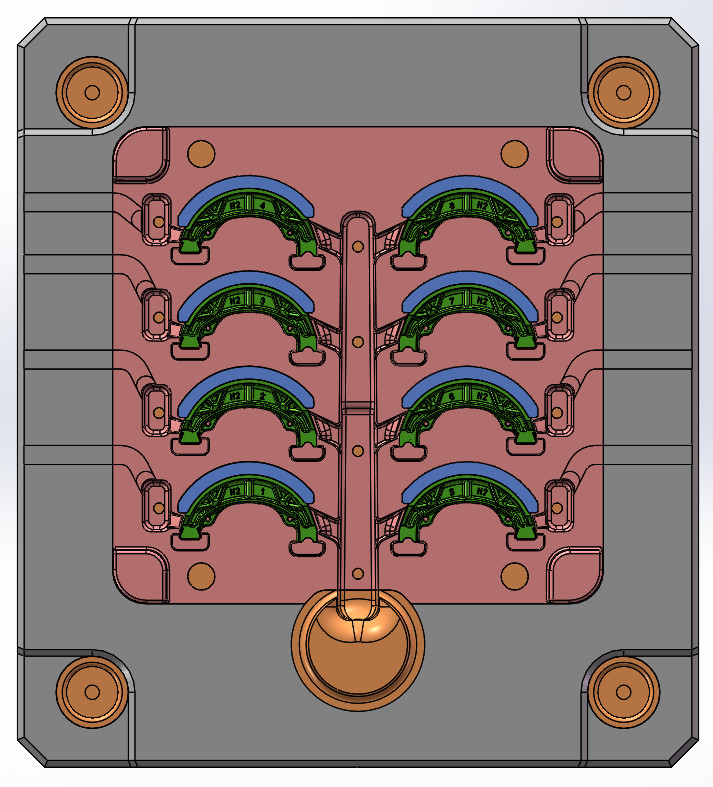

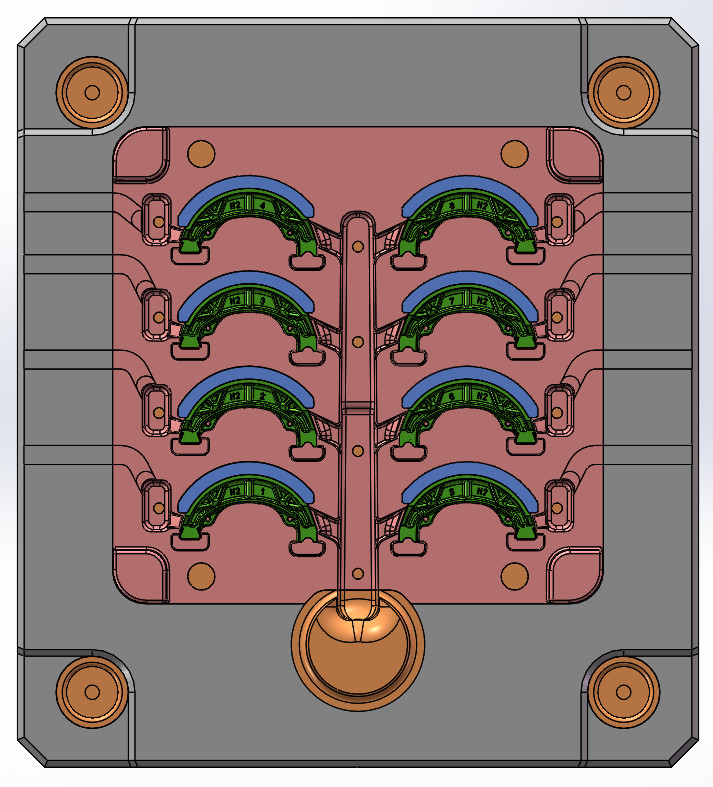

This picture shows a part, gate, and venting system of an 8 cavity die. The projected surface area of this gate is 214.6 square inches.

We also must know the metal pressure required to successfully produce this casting. Most castings will be produced with 10,000-12,000 PSI of metal pressure.

The tonnage required to cast this 8 cavity design is calculated by multiplying the metal pressure by the projected area.

Machine Tonnage Required = (Projected parting line area X Metal Pressure) / 2000

This particular design requires (214.6*10,000)/2000 = 1073 tons or a 1000 ton machine.

The die caster will perform a cost evaluation during quoting to determine the most cost-effective solution for the customer using their equipment.

For example, this particular part could be produced in 2, 4 or 8 cavity die. The following table contains illustrative numbers to explain how cavitation effects tooling and casting price.

|

|

2 |

4 |

8 |

|

Machine Size (tons) |

400 |

600 |

1000 |

|

Estimated Annual Usage |

500,000 |

500,000 |

500,000 |

|

Cycle Time |

30 seconds |

40 seconds |

50 seconds |

|

Annual Hours Required |

2083 |

1388 |

868 |

|

Machine Cost/Hour |

$200 |

$250 |

$300 |

|

Piece cost w/o metal |

$.83 |

$.69 |

$.52 |

|

Tooling Cost |

$60,000 |

$85,000 |

$110,000 |

|

Tooling life Yield in pieces: 100,000 shots/5% Scrap |

190,000 |

380,000 |

760,000 |

|

Life or Project |

5 years |

5 years |

5 years |

|

Number of replacement cavities required |

14 |

7 |

4 |

|

Total project tooling cost |

$520,000 |

$420,000 |

$280,000 |

|

Total project casting cost |

$2,075,000 |

$1,725,000 |

$1,300,000 |

|

Total project cost |

$2,595,000 |

$2,145,000 |

$1,580,000 |

When referring to the chart above, it is evident that while the 8 cavity die has the highest upfront tooling cost, it has the lowest overall cost for the project. Each time replacement cavities are constructed they must be sampled and PPAP approved. This process adds additional costs that should be considered as well.

Typically, maximizing the number of cavities reduces the piece price and the overall cost of the project. However, economics can change as machine size increases.

400 ton to 1000 ton machines are very common in the die casting industry. Machine tonnage 1200 to 4500 are less common and are typically used for high-volume automotive work. 1200 to 4500 machines are much more expensive to purchase and operate which makes the cost higher. Most of these machines were purchased to specifically produce a large casting such as an engine block or transmission cast. While It may be possible to build a 50 cavity die of your part to run on a 3000 ton machine, they are typically reserved for large, high volume castings.

Complexity of the casting

The complexity of the casting will impact your decision in several ways. The number of slides, the dimensional tolerances, and the geometry of the casting all must be considered.

Number of slides

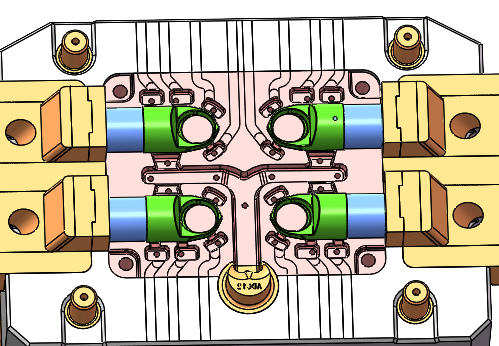

If the casting has multiple slide cores, it will limit the number of cavities that can be used. The moving slide mechanisms consume space in the die and create a physical constraint on cavitation.

This design shows a 2 cavity die with 4 slides on each cavity. While a 4 cavity die is possible, the complications created during production may outweigh the benefits. Cavitation greater than 2 cavities should only be considered if operating multiple dies simultaneously is required to meet demand.

Dimensional Control

Each additional cavity in the die adds to the challenge of dimensional consistency. Let’s say your casting has 4 features that require a tight tolerance to be held. This is very manageable in a 2 cavity die with a total of 8 critical features per machine cycle. If you build an 8 cavity die, then you have 32 critical features to control each cycle. While this can be accomplished, it often requires much more frequent die maintenance which adds cost. This is particularly true when each cavity has one or more slides.

Difficult geometry and quality requirements

With each additional cavity, the runner and venting system becomes more difficult to design. The caster will engineer the runner to fill each cavity at the same time. Even with modern computer modeling, it is very challenging to optimize runners and venting systems on high cavity dies. The die caster may advise against higher cavities when it compromises quality.

Annual Usage

Our earlier example presented a high volume casting at 500,000 pieces per year. The economics change when the part is lower volume. Let’s say the volume is 15,000 pieces per year and a 5 year project life. In this example the lowest project cost is a 2 cavity die.

|

|

|

|

|

|

cavities |

2 |

4 |

8 |

|

Machine Size (tons) |

400 |

600 |

1000 |

|

EAU |

15,000 |

15,000 |

15,000 |

|

Cycle Time |

30 |

40 |

50 |

|

Annual Hours Required |

62.5 |

41.7 |

26.0 |

|

Machine Cost/Hour |

$200 |

$250 |

$300 |

|

Piece cost w/o metal |

$0.83 |

$0.69 |

$0.52 |

|

Initial Tooling Cost |

$60,000 |

$85,000 |

$110,000 |

|

Tooling life Yield in pieces: 100,000 shots/5% Scrap |

190,000 |

380,000 |

760,000 |

|

Life or Project |

5 |

5 |

5 |

|

Number of replacement cavities required |

1.0 |

1.0 |

1.0 |

|

Replacement |

$40,000.0 |

$60,000.0 |

$80,000.0 |

|

Total project tooling cost |

$100,000 |

$145,000 |

$190,000 |

|

Total project casting cost |

$62,500 |

$52,083 |

$39,063 |

|

Total project cost |

$162,500 |

$197,083 |

$229,063 |

Each die casting project is unique. It is important to review the scenarios with your die caster before beginning your project. At Seipo our staff of Sales and Tooling Engineers can guide you in the proper direction. Contact us for your next die casting project!