Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

High pressure die casting

2021-01-11 10:49:09

Lightweight, durable, precision-made, high-temperature resistant aluminum die-casts.

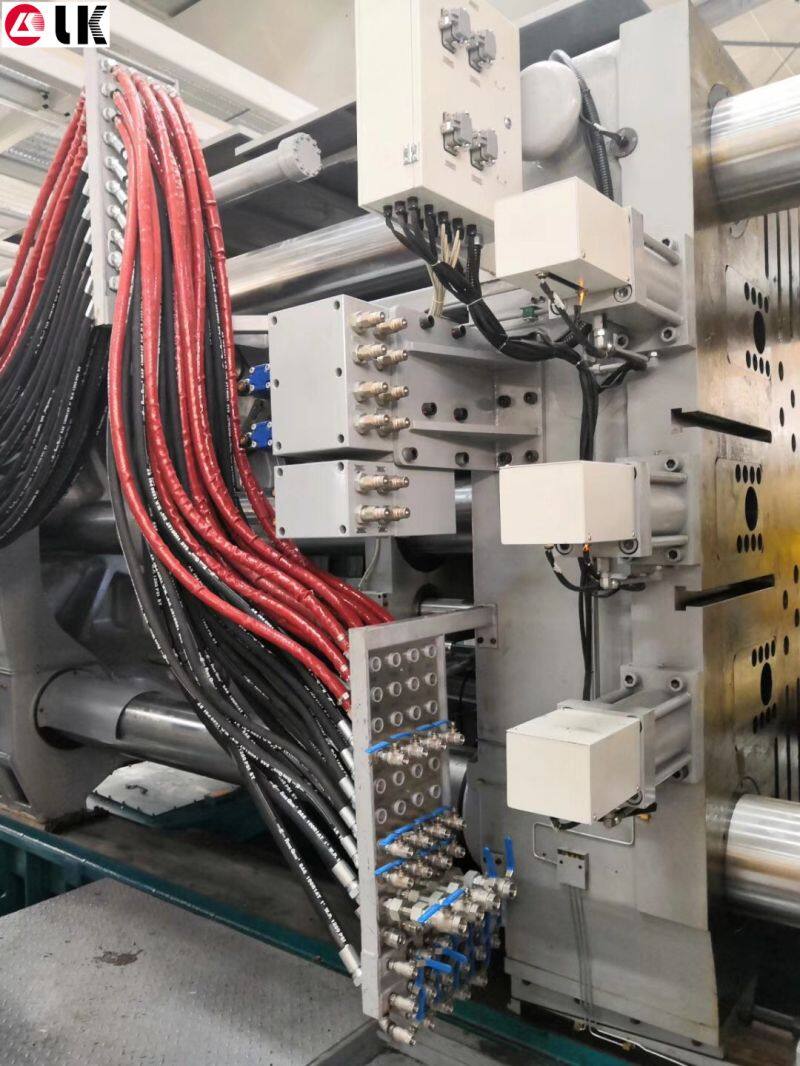

aluminum high Pressure Die Casting Machine

The aluminum die casting process begins with an accurate check and appropriate preparation of the production alloy in melting furnaces. This first stage is crucial for the final casting, which is characterized by its predefined structure and strength.

In the second stage, the melted aluminum is transferred to a holding furnace from which it is fed to a shot sleeve and injected directly through a piston into the cavity of a die casting mold.

High-pressure aluminum die casting is carried out by a horizontal cold chamber machine. To increase work efficiency, casting accuracy, and the overall quality of manufactured products, the die casting process is automated.

LK is able to afford to implement autoated aluminum dosing, ladling, mold spraying, and die cast extraction systems.

Contact us