Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

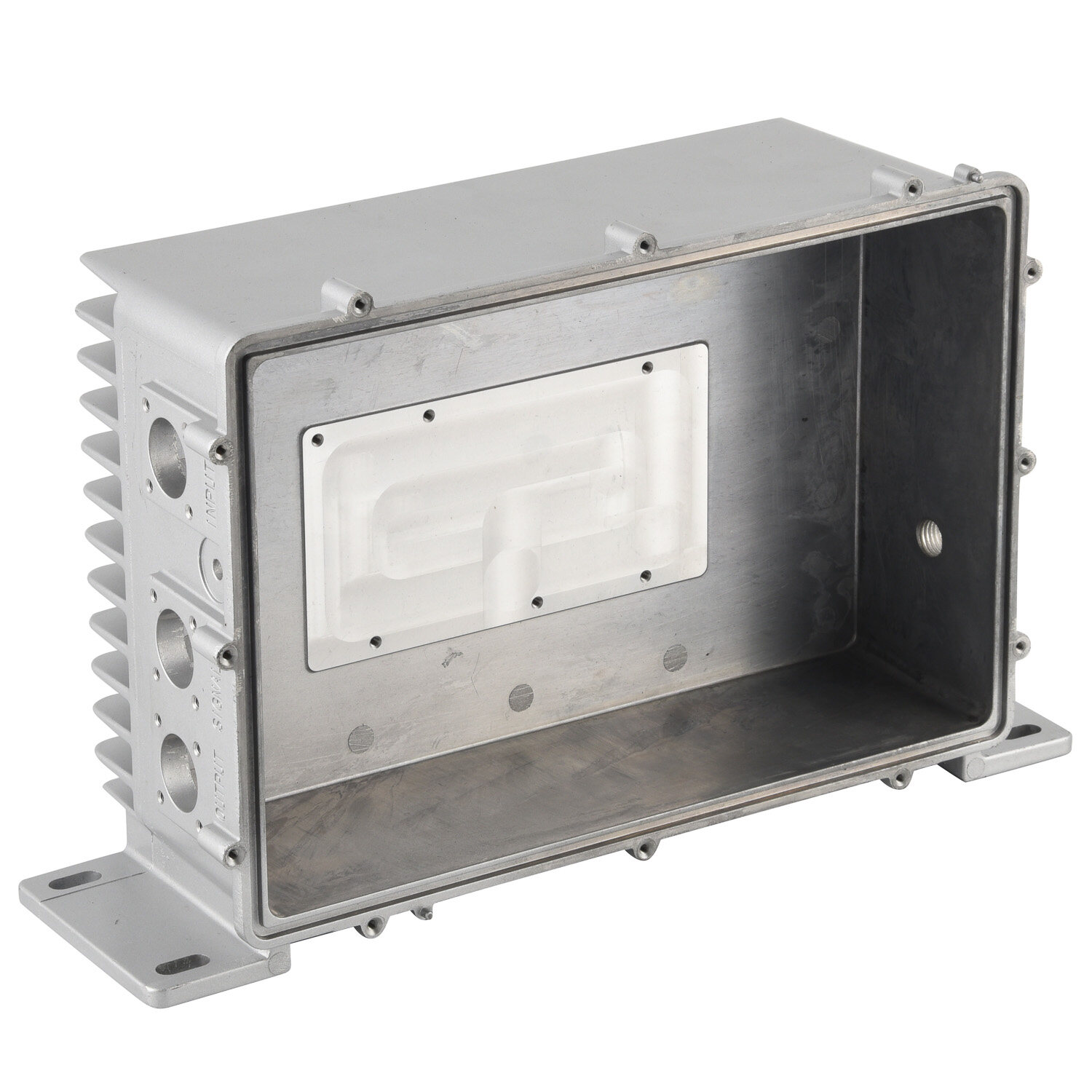

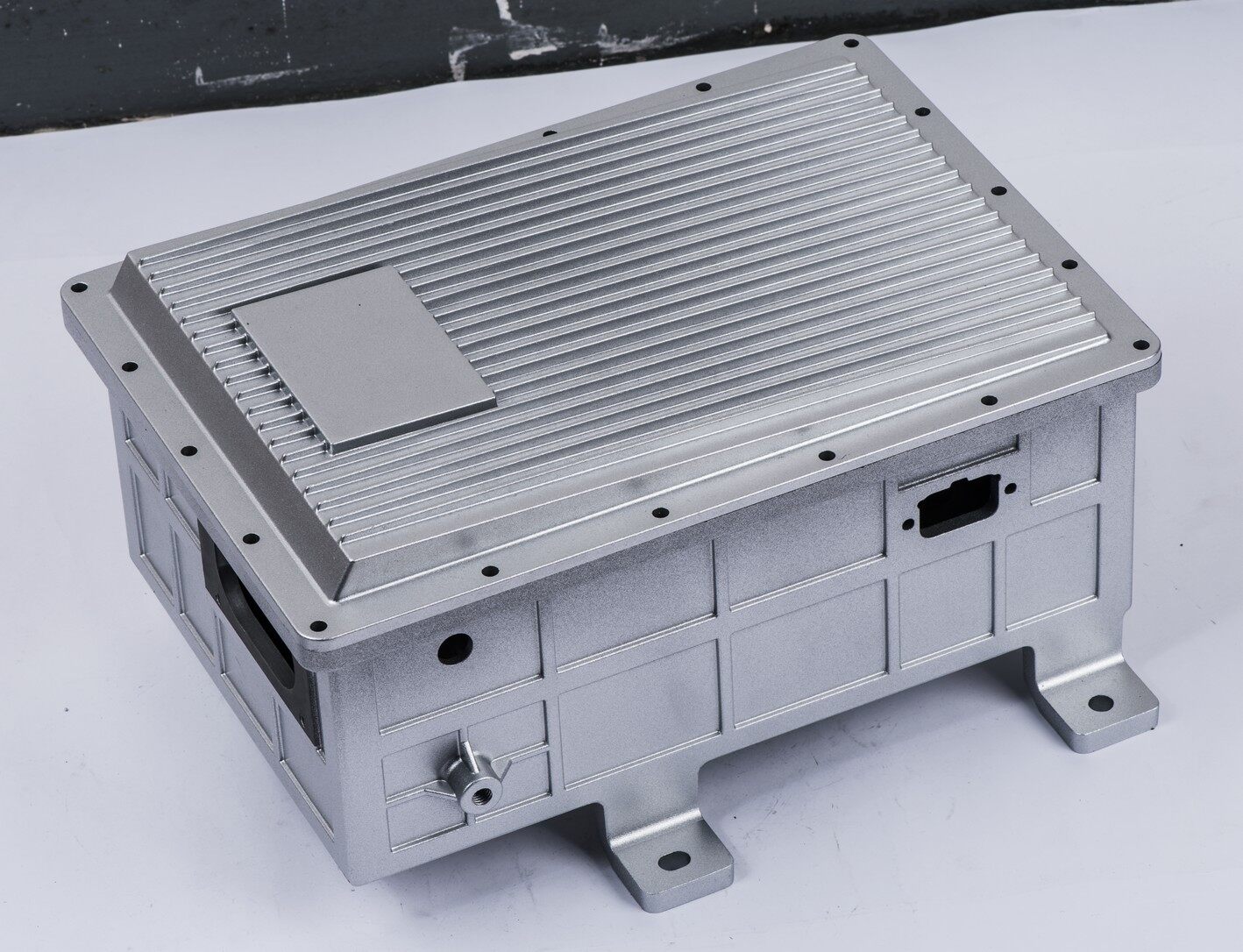

High-Quality Aluminum Die-Casting Lids by SEIPO: Precision, Durability & Custom Solutions

SEIPO specializes in manufacturing premium aluminum die-casting lids for industrial, packaging, and electronics applications. Discover our custom solutions, fast delivery, and ISO-certified quality.

Why Choose SEIPO Aluminum Die-Casting Lids?

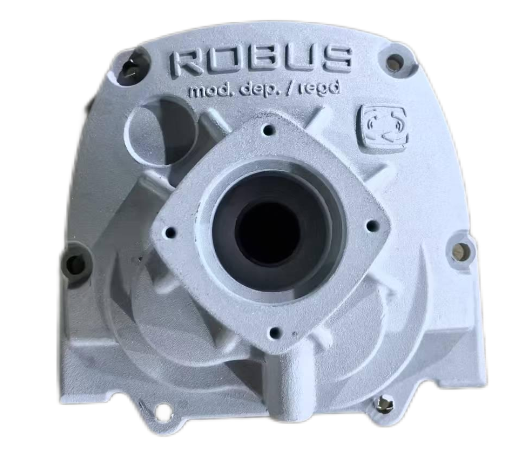

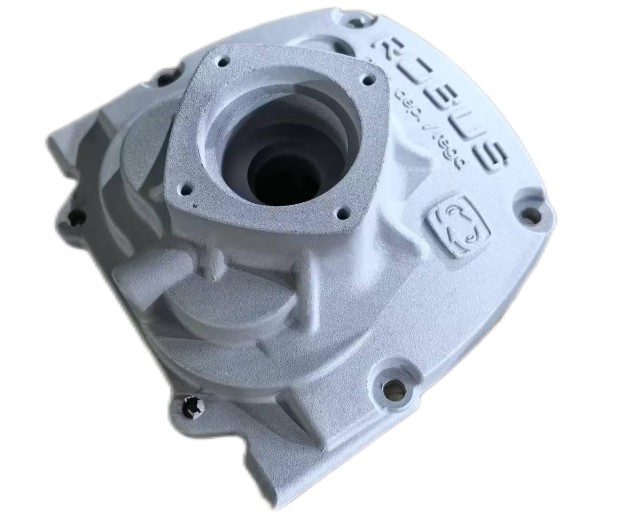

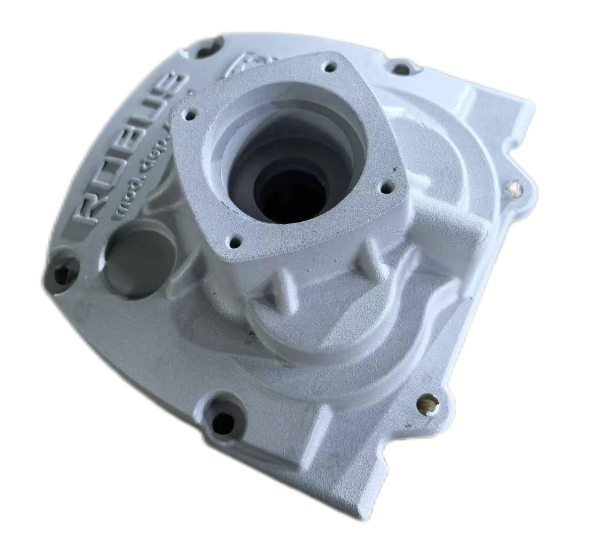

Precision Engineering for Diverse Applications

SEIPO leverages advanced aluminum die-casting technology to produce high-tolerance lids tailored for industries such as:

Food & Beverage Packaging: Airtight, corrosion-resistant lids for containers and jars.

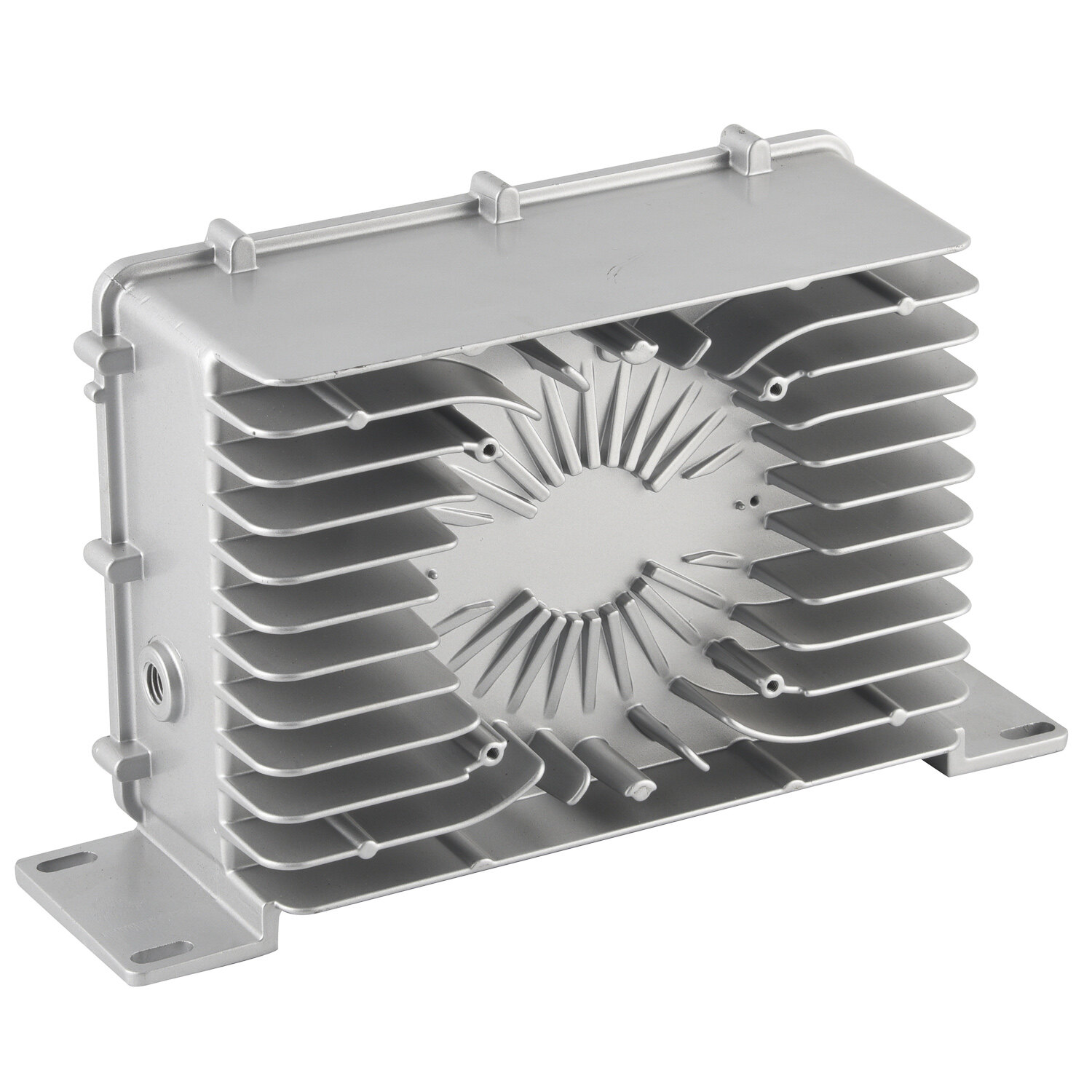

Electronics: EMI-shielded lids for sensitive device housings.

Automotive & Industrial: Heat-resistant components for engines and machinery.

Customization to Meet Your Needs

Design Flexibility: From intricate geometries to brand-specific engravings.

Material Options: ADC12, A380, and eco-friendly alloys.

Surface Finishes: Anodizing, powder coating, or polishing for enhanced aesthetics.

Fast Turnaround & Competitive Pricing

Prototypes delivered in 7–10 days with no MOQ restrictions.

Bulk production optimized for cost-efficiency without compromising quality.

Key Advantages of SEIPO’s Die-Casting Process

✅ High Pressure Die Casting (HPDC): Ensures uniform density and minimal porosity.

✅ ISO 9001 & IATF 16949 Certified: Rigorous quality control for defect-free products.

✅ Sustainability Focus: Recyclable materials and energy-efficient production.

Applications of Aluminum Lids

Pharmaceuticals: Tamper-evident seals for pill bottles.

Consumer Goods: Sleek, lightweight lids for cosmetic packaging.

Renewable Energy: Durable covers for solar panel junction boxes.