Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

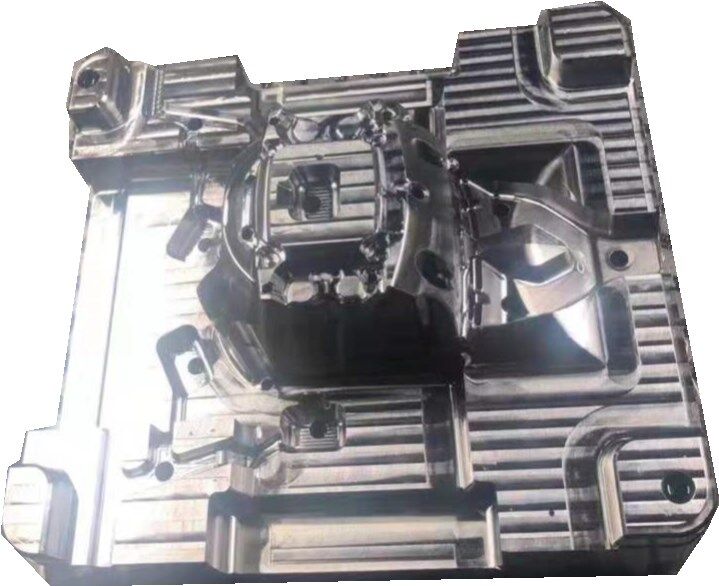

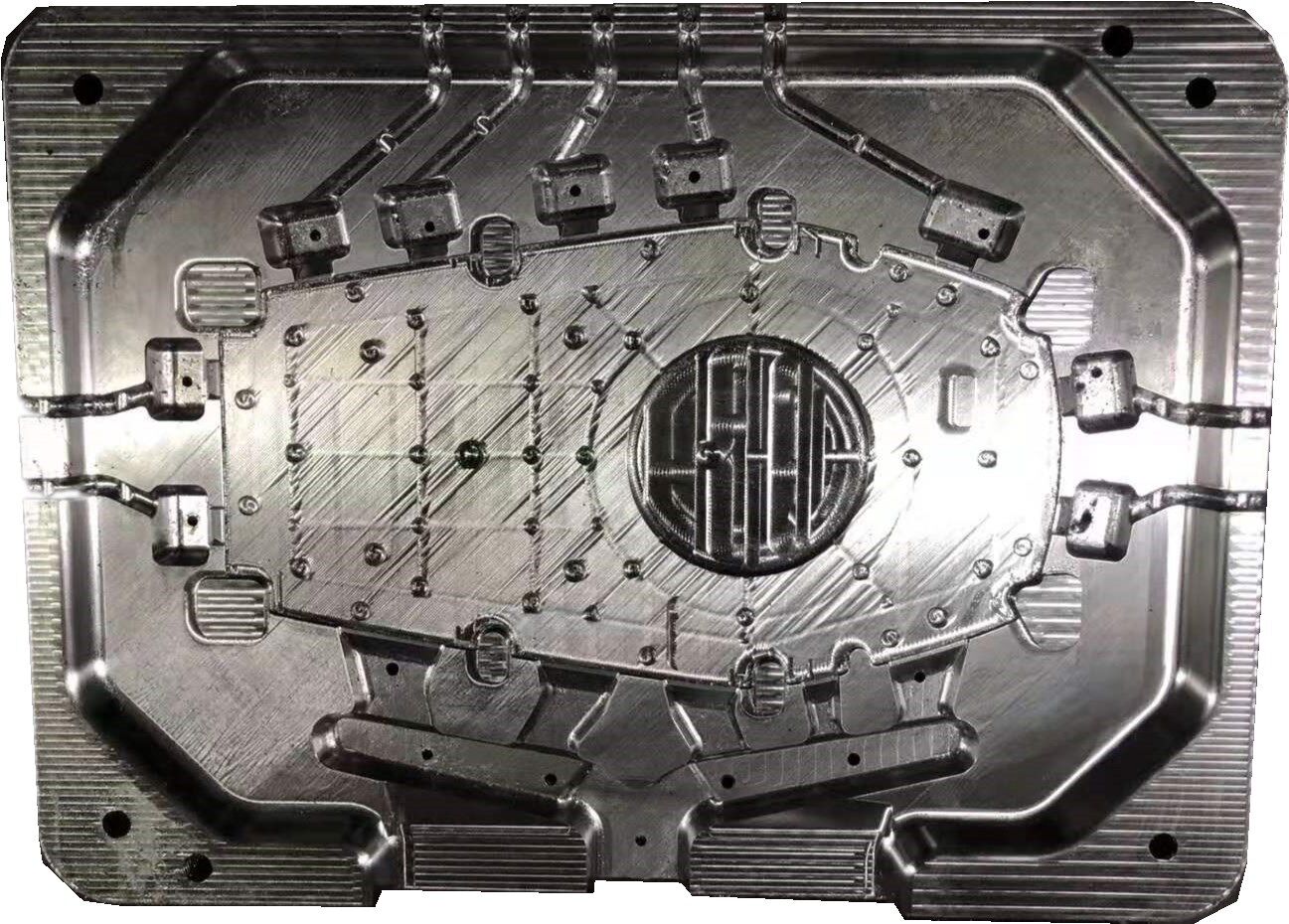

HPDC mold

HPDC mold

-

USD 1,000.00 ~ USD 100,000.00/

1/ (Min. Order)

Contact us

Inquiry Basket

Product Code:

8480719090

OEM:

Available

Sample:

Refuse

Port:

Ningbo

Payment:

PayPal,Other,VISA,MasterCard,Western Union,L/C,T/T,D/P,D/A

Place of Origin:

China

Supply Ability:

15 per Month

Color

as metal

High Pressure Die Casting Mold Benefits

There are numerous advantages regarding the usage of the die casting (or HPDC) process. At Saige, we can provide you with die-cast molds that match your design specifications. Some of the advantages and disadvantages of the HPDC molds process include the following:

HPDC Mold Advantages

Net shape part configuration is achievable

High dimensional accuracy is achievable

Fast production

Thinner walls are achievable when compared to investment and sand castings

Wide range of possible shapes

External threads can be casted

Steel inserts can be over-molded

Holes can be cored to internal tap drill size

HPDC Mold Disadvantages

A relatively large production volume is required to make the process cost-effective. (However, Saige would work with customers ways to mitigate this shortcoming.)

High initial cost (tool, set up)

Minimum wall thickness: 0.040"

Maximum wall thickness: 0.200". In some cases, acceptable up to 0.50"

Draft radii and fillets required on the casting

Potential porosity issue

Contact us