Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Importance of Automation in Die Casting

The Importance of Automation in Die Casting

Die casting and automation is not a new concept. Today, with innovations in robotics, vision systems, and AI, automation in manufacturing is more critical than ever before. Continue reading to learn how automation can benefit your organization’s die casting needs.

Automation Benefits in Die Casting

At first glance, die casting can look like a simple process that may not benefit from automation. Most people think about die-casting the envision metal being melted in a furnace and poured into a die to solidify. However, automation is crucial in the die casting process, as it streamlines production, improves quality, and reduces operating costs.

A die casting machine running with automation has a faster and more stable cycle time and a more consistent spray pattern. A consistent cycle time results in a balanced die temperature which yields longer die steel life and less scrap.

In addition to cost savings and improved quality, there are also many safety benefits that automation provides in die casting. Automation minimizes molten metal and high-temperature component contact with workers as well as eliminating repetitive tasks and heavy lifting.

Additional benefits of automation include:

· Consistent results in every time, even with the most precise operations

· Faster part-to-part cycle time which increases productivity

· Less waste production, saving customers money on raw materials and cleanup

To achieve repeatability and reliability, General Die Casters utilizes Fanuc 6 axis robots to do part extraction, part sensing, and quenching. The value of a robot is limited only by imagination. We have utilized our robots to perform error-proofing inspections and operations as well as remove gates and overflows to streamline the trim operation.

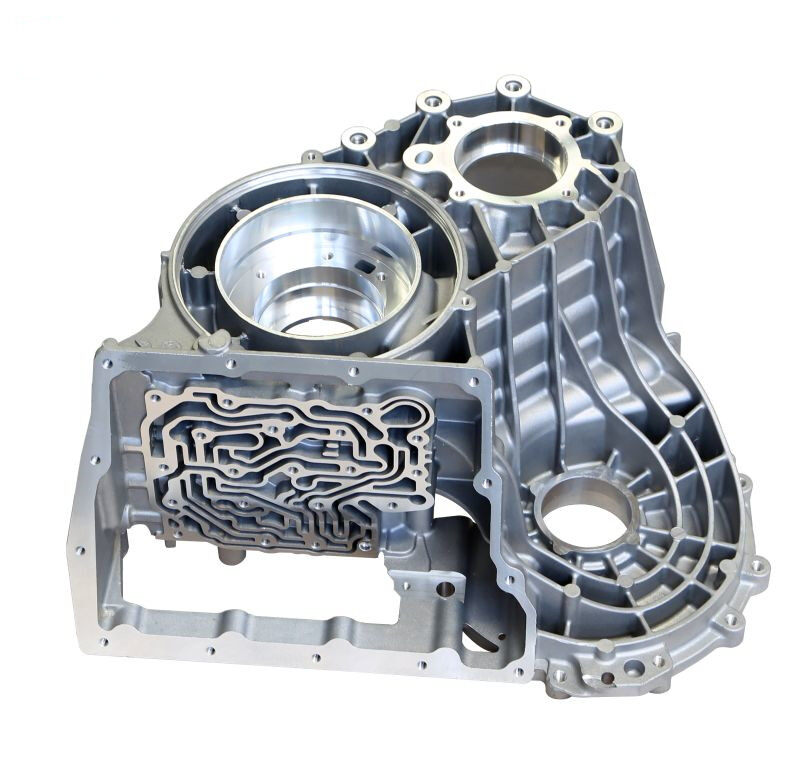

Robots are now commonly used to replace trim dies on large, single cavity dies such as engine blocks and transmission cases. This reduces tooling costs and increases the flexibility of the cell.

While automation is important, we believe that our success lies in our team. While some die casters tout the ability to ship a casting never touched by human hands, we have a different philosophy. We choose to have an educated member of our team handle and inspect every part. This is just one of the many steps we take to ensure that we are truly providing the highest level of quality and service.

The keys to successful die casting automation are process control and equipment maintenance. If the production equipment and die design are not capable of consistently meeting performance standards, then the automation cell becomes an efficient recycling machine. We utilize a structured Total Preventive Maintenance Program with equipment performance tests to ensure our machines and dies are always capable of meeting production goals.